-

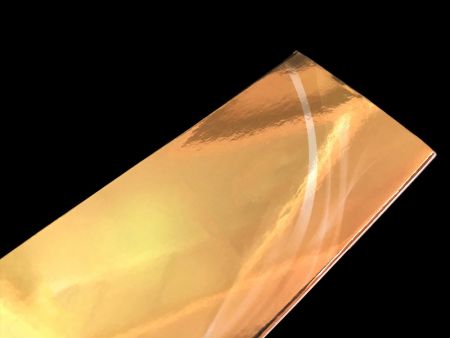

Translucent Foil

Translucent foil has differ production process from the general hot stamping foil, which could perform different effects, by applying translucent foil onto the printed colors will create thousauds of combinations with special layering effects. Many cosmetics related industries and designers are using our translucent foils in packaging designs and creating the unique style. Our translucent foils have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

-

Cold Stamping Foil

Cold Stamping Foil technology is often used in printingindustry. One of its advantages is that several colors can be applied at the same time, it's timesaving, eco-friendly,and diversified in colors. Using UV resin to perform transferring onto the substrates, proceeds with lamination by using laminating rolls followed by UV hardened system. It could be classified into narrow-web printing and offsetprinting, the former often used in printing labels and thelatter more for printed matter.

-

Rainbow Metallic Film

Certified High-End Packaging Solution for Luxury and Fashion Industries

Rainbow Metallic Film is a decorative hot stamping foil material that has passed rigorous international certifications, including En71-3, CP65, REACH, RoHS, and SGS, ensuring the product's environmental friendliness and safety. We conduct comprehensive quality inspections to ensure that your product performs optimally in the market, meeting the demands of the high-end sector. Rainbow Metallic Film is widely used in fashion apparel decoration and cosmetics packaging. It utilizes advanced coating technology to give products a unique rainbow sheen, enhancing their aesthetic appeal. Whether for brands with special design requirements or companies looking to highlight a premium feel, Rainbow Metallic Film is the ideal choice.

-

Lamination Film

Lamination film could be fully attached to various substrates such as plastic and paper, allowing them to exhibit gloss. The difference between hot stamping foil and lamination film is the PET film layer is kept after the laminating process, leaving an extra protection to the surface of the products, keep moisture and oxygen away. It could work as a protective film. It also has better abrasion resistance and scratch resistance than general hot stamping foil, and have great adhesion to various substrates such as labels, greeting cards, wine bottles, packaging paper boxes, lampshades, etc.

-

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.

-

Hot Stamping Foil for Glass and Ceramics

Designed for Premium Products, Combining Luxury and Durability

Glass and ceramic hot stamping foil is a high-performance metallic transfer film specifically designed for glass hot stamping processes and ceramic applications. It is ideal for premium products such as perfume bottles, cosmetic bottles, wine bottles, and decorative vases. This product not only delivers exceptional high-gloss hot stamping effects but also offers the durability of scratch-resistant glass transfer and the stability of alcohol-resistant hot stamping, making it the perfect solution to meet the demands of the high-end market. Moreover, the product complies with multiple environmental and safety certifications, including REACH, RoHS, EN71-3, and CP65, ensuring market safety. Environmentally certified hot stamping foil not only enhances product value but also meets the stringent environmental requirements of the international market. Whether you aim to enhance the visual appeal of your products or strengthen their functionality, our hot stamping foils will help you stand out in the competitive market.

-

Functional Hot Stamping Foils

Functional stamping foils with Ginkgo's state-of-the-art metalizing and coating technologies, our foils can provide a comprehensive range of functions according to customers' needs. For instance, the lamination film gives an extra layer of protection to keep moisture and oxygen out. The holographic foil has unique and unreproducible patterns; hence, it's perfect for anti-counterfeit labels. The release film with stable release force and the excellent uniformity of the coating layer makes it suitable for products made of composite materials utilized by the semiconductor industry. Exterior foil has properties of adequate environmental resistance, scratch resistance, oxidation resistance, etc. Hard coating film could strengthen the products' hardness and make them better abrasion-resistant. The applications above can utilize our lamination film, exterior foil, release film, printable release film, hard coating film, plastic packaging hot stamping foil, transfer film for leather, transfer film for textile, digital foil, holographic foil, hot stamping foil for glass to achieve a multiple-function for the product's specific requirements. In addition to their functions, the foils also give your products the aesthetic features to distinguish you from others. All products have undergone stringent inspection and passed rigorous certification processes such as En71-3, CP65, REACH, RoHS, and SGS in order to offer customers the best quality. This ensures that when your products are introduced to the global market, they will be able to meet local standards for performance, quality, and safety. market-specific demands.

-

Decorative Hot Stamping Foils

Hot stamping foil gives a different appearance to the product. Ginkgo can provide various decorative foils for multiple materials, adjust according to different physical properties and produce suitable foils to meet customers' needs in numerous industries. Our hot stamping foils have passed at least nine quality tests, including but not limited to alcohol resistance, detailed definition, release force, etc. Ginkgo focuses on every detail, from complete surface stamping to clear letters or graphics; we can create perfect and elegant products by utilizing hot stamping foils. Packaging with decorative foils has an incredible visual effect while establishing the brand image and elevating product value. You can see many everyday products with hot stamping foils, such as cosmetics packaging, electronic appliances, automobile decoration, glass bottles, stationery, textiles, ribbons, clothing, leather, etc. To fulfill the abovementioned applications, Ginkgo offers customers a comprehensive portfolio, such as translucent foil, cold stamping foil, pearlescent foil, NeoIris film, rainbow film, glitter film, eco-friendly glitter film and so forth. For instance, hot stamping foil can add glamour to cosmetic packaging designs, bringing out the product's highlights and dramatically enhancing the company's brand image. The metallic luster from the transfer film can elevate the product's fineness on the leather surface; the unique glossy design on the glass bottles creates a visual sensation with glass foil; The digital foil on the posters amplifies the details of the design work. All products have undergone stringent inspection and passed rigorous certification processes such as En71-3, CP65, REACH, RoHS, and SGS in order to offer customers the best quality. This ensures that when your products are introduced to the global market, they will be able to meet local standards for performance, quality, and safety. market-specific demands.

- Home Homepage

- Company Company Profile

- Customized Foil Foil Design Services

- Products Stamping foil & film

-

Application Industrial Application

- Plastic hot stamping foils for packaging design applications

- Plastic hot stamping foils for appliances and electronics

- The best combination of textile transfer films and fabric prints

- Foils for water transfer decals and stickers

- Glass hot stamping foils for glass decorations

- Exterior foils with chrome-metalized for the automotive industry

- Transfer films for leather and fabric applications

- Holographic foils for anti-counterfeiting and decoration applications

- Hard coating films for scratch-resistant application

- Lamination films for paper and cardboard applications

- Release films for the electronics, optical, and printing industry

- Cold foils for the printing industry

- FAQ Common questions

- Contact Us Send an Inquiry