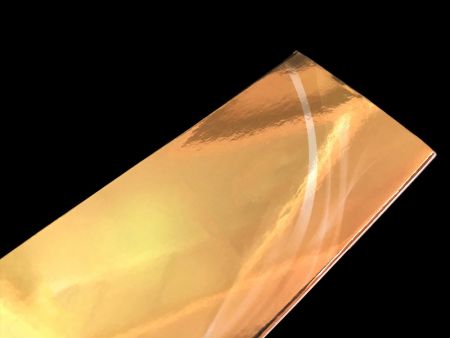

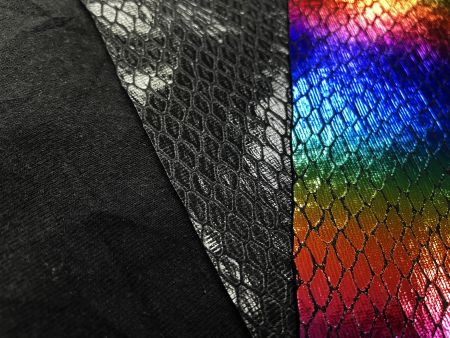

Transfer films for leather and fabric applications

Suitable for wallets, bags, shoes, and ribbons.

Ginkgo has been focusing on developing leather transfer films for decades. Our transfer films can be applied on various substrates, such as genuine leather, synthetic leather, nylon, cotton, and polyester. The customers utilize transfer films for partial and full-surface decorations, and the metallic luster from films can bring out the designs' distinctive features.

Because of an extensive portfolio of colors alongside a high covering power and edge definition features, Ginkgo's transfer films are always the inspiration for international brands, designers, the leather industry, the textile industry, and hot stamping factories.

Vision and evolution of leather transfer films

Ginkgo keeps developing and upgrading our transfer films' definition, abrasion resistance, resilience, and adhesion. And Ginkgo aims to create more possibilities with our innovative transfer films and solutions.

If you need leather transfer films, please refer to the "products" below, or click the "contact us" above and let us help you.

Sales region

Due to our leather transfer films' brilliant and reliable quality, Ginkgo has provided our transfer films over Bangladesh, China, Europe, India, Japan, Philippines, Syria, Taiwan, and Turkey.

If you are interested in our products, please don't hesitate to contact us. Ginkgo will provide the best solution for you while delivering consistency and reliability.

Related Info

- Types of Suitable Material: Genuine Leather, PU Leather, Artificial Leather

- Working Process: Roll Stamping

- Related Products

Lamination Film

Lamination film could be fully attached to various substrates such as plastic and paper, allowing them to exhibit gloss. The difference between hot stamping foil and lamination film is the PET film layer is kept after the laminating process, leaving an extra protection to the surface of the products, keep moisture and oxygen away. It could work as a protective film. It also has better abrasion resistance and scratch resistance than general hot stamping foil, and have great adhesion to various substrates such as labels, greeting cards, wine bottles, packaging paper boxes, lampshades, etc.

Transfer Film for Leather

Transfer film for leather has excellent resilience, adhesion, and abrasion resistance. It is unlikely to break during the manufacturing process. It is transferred onto substrates such as leather, PU, and PVC through the heat and pressure generated in the hot stamping process, adding metallic luster to the products which could not be accomplished by using dyes therefore adding value to products. Our products have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

Transfer Film for Textile

Hot stamping film for textile by partial transferring the metal on film onto the substrate, it gives the metallic texture and shine and adds values to the products. What's different to transfer film for textile is that the stamping process is easier and hence it is usually used in stamping patterns onto elastic bandages, textile, ribbons for gifts, T-shirt, fashion outfits, etc.