Foils for water transfer decals and stickers

Suitable for water transfer decals, self-adhesive stickers, hologram decals

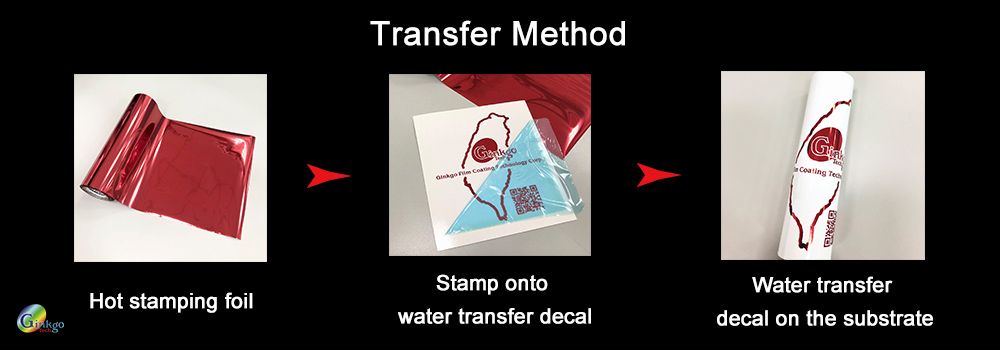

Ginkgo has developed a unique series of foils for water transfer decals and sticker applications. Unlike the general foils that can only stick to plastic or paper substrates, this special foil can adhere to the metal surface with these water transfer decals. Furthermore, foils also give the water transfer decals the glossy metallic effect, which cannot achieve with ordinary printing.

Foils for water transfer decals also create more possibilities with high curved or uneven surfaces that cannot stamp onto by the traditional stamping process. Because of its excellent elasticity, this application is well-received in the decorations such as helmets, bicycle frames, and golf clubs.

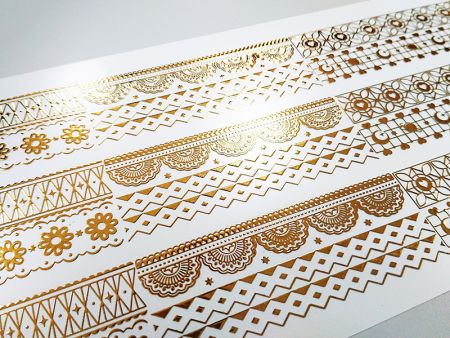

With Ginkgo's special foils' excellent transfer workability and multiple hologram patterns, our foils are always the favorite of many international brands, the printing industry, the bicycle industry, the motorcycle industry, and the water transfer decal manufacturers.

Vision and evolution of special foils for water transfer decals

Ginkgo keeps improving the characteristics of foils and creating up-to-date designs. And provide the best solution to cater to all customers' needs in the future.

If you need foils for water transfer decals, please refer to the "products" below, or click the "contact us" above and let us help you.

Sales region

Ginkgo has provided this special foil over Asia and Europe for many years.

If you are interested in our products, please don't hesitate to contact us. Ginkgo will provide the best solution for you while delivering consistency and reliability.

Related Info

- Types of Suitable Material: Water Transfer Decals

- Working Process: Roll-On Stamping, Vertical Stamping

- Related Products

Holographic Foil

Holographic foil requires excellent hologram embossing technology to display a special appearance and catch customers' attention. The foil is often used in hot stamping on various papers and plastic materials and facilitate decorative functions. It could be applied to cosmetics, paper box, lure bait, credit card, passport, and anti-counterfeit label, it is flexible and available for satisfying different, customized layouts, colors, and patterns.

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.

Digital Foil

Digital foil is digital printing with metallic touch. Injecting UV varnish on substrates such as general paper, printing paper, OPP lamination material, and polyethylene terephthalate material. Processed through UV hardened system and hot stamping. Metallic shine transferred onto UV varnish brings out the glossy effects on products and shows the finest details.