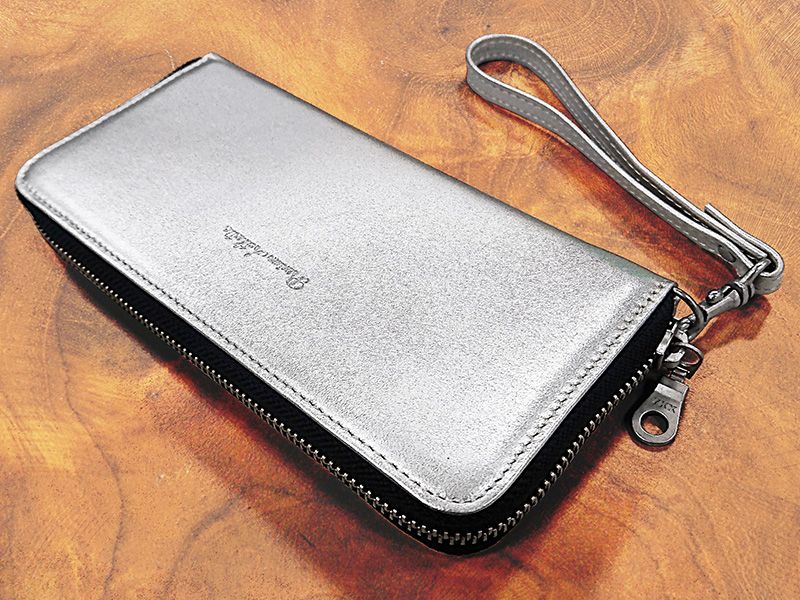

Transfer Film for Leather

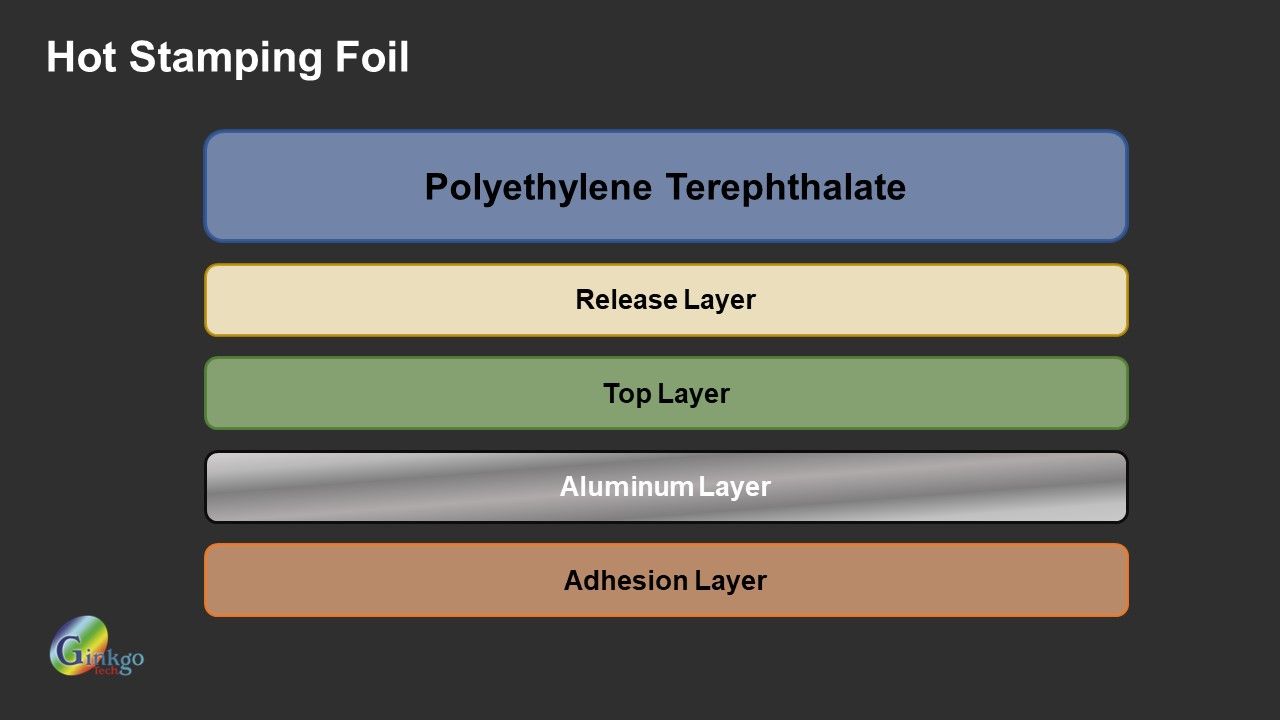

Transfer film for leather has excellent resilience, adhesion, and abrasion resistance. It is unlikely to break during the manufacturing process. It is transferred onto substrates such as leather, PU, and PVC through the heat and pressure generated in the hot stamping process, adding metallic luster to the products which could not be accomplished by using dyes therefore adding value to products. Our products have passed strict certifications and verifications process of En71-3, CP65, REACH, RoHS, and SGS. We conduct all-round inspections to ensure safety of your products in the market.

Features

- Enables high gloss.

- Excellent resilience.

- Good adaptability to processing.

Specification

- Applicable Materials: Paper, PVC, fabric, synthetic leather, etc.

- Color Options: Customizable according to customer requirements, catering to different design styles and application scenarios.

- Hot Stamping Temperature Range: 140°C - 200°C, suitable for diverse application processes.

- Standard Size: 640mm x 120M, or customizable based on customer needs.

Ordering Information

- Minimum Order Quantity: Depending on required specifications. (Please contact our sales representatives for confirmation).

- Lead Time:Defined productions and inspections are based on your requirements. (Please contact our sales representatives for confirmation)

- Video

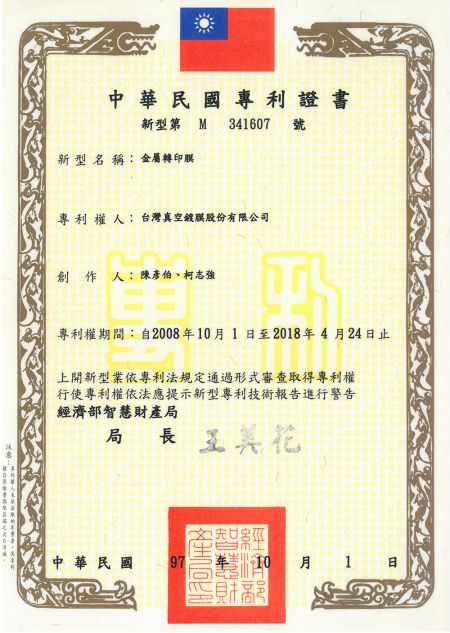

- Certificate