-

ProfessionalTrustworthy

ProfessionalTrustworthy -

InnovationQuality

InnovationQuality -

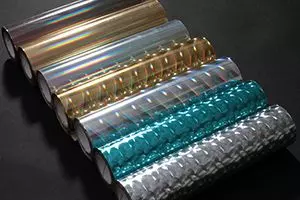

Multiple ColorOptions

Multiple ColorOptions -

Looking forReliable Partners

Looking forReliable Partners

Your all-round solution for foils.

Ginkgo's hot stamping foil have high quality and various options. To reach the goal of sustainable development and green company, other than ISO 9001 certification, we also introduced RTO thermal oxidizer to avoid hazardous substance.

Over 30 years of experience in foil process.

Hot stamping film's applications cover many aspects in life regarding clothing, food, housing, and transportation.

Meanwhile, we're actively making our business thrive by exposing our products in the international market.

Hot Products

Hot Stamping Foil for Plastic

Hot stamping foil for plastic packaging is most often used product which could be applied to soft tube or rigid...

Read More

Holographic Foil

Imaging technology of holographic stamping foil not only guarantees authenticity security but also catches...

Read More

Glitter Film

Decorative glitter film has features of good scratch resistance, and physical property. Could be applied to making...

Read More