Transfer Film for Textile

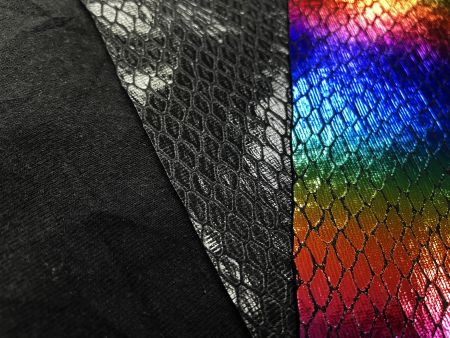

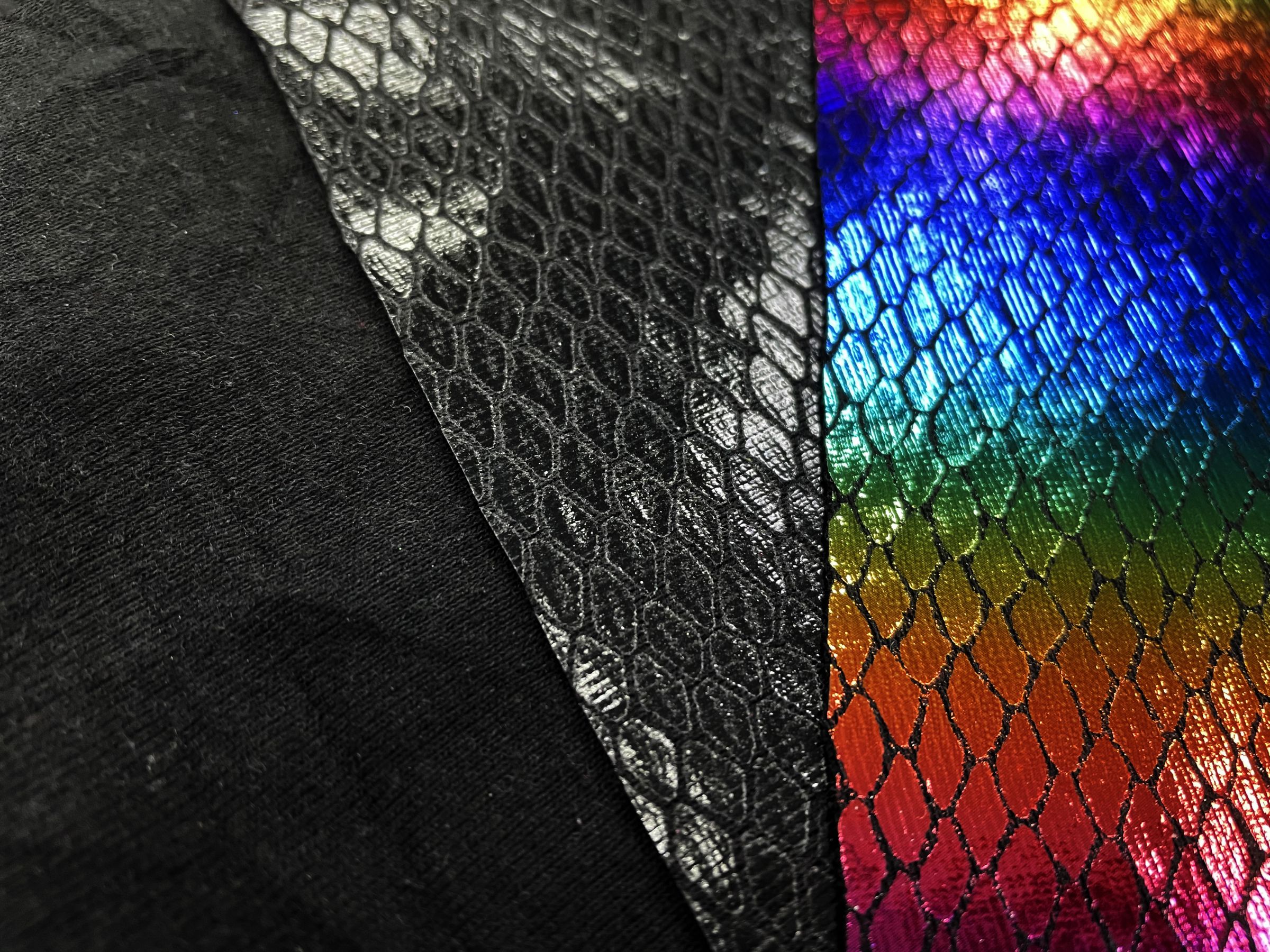

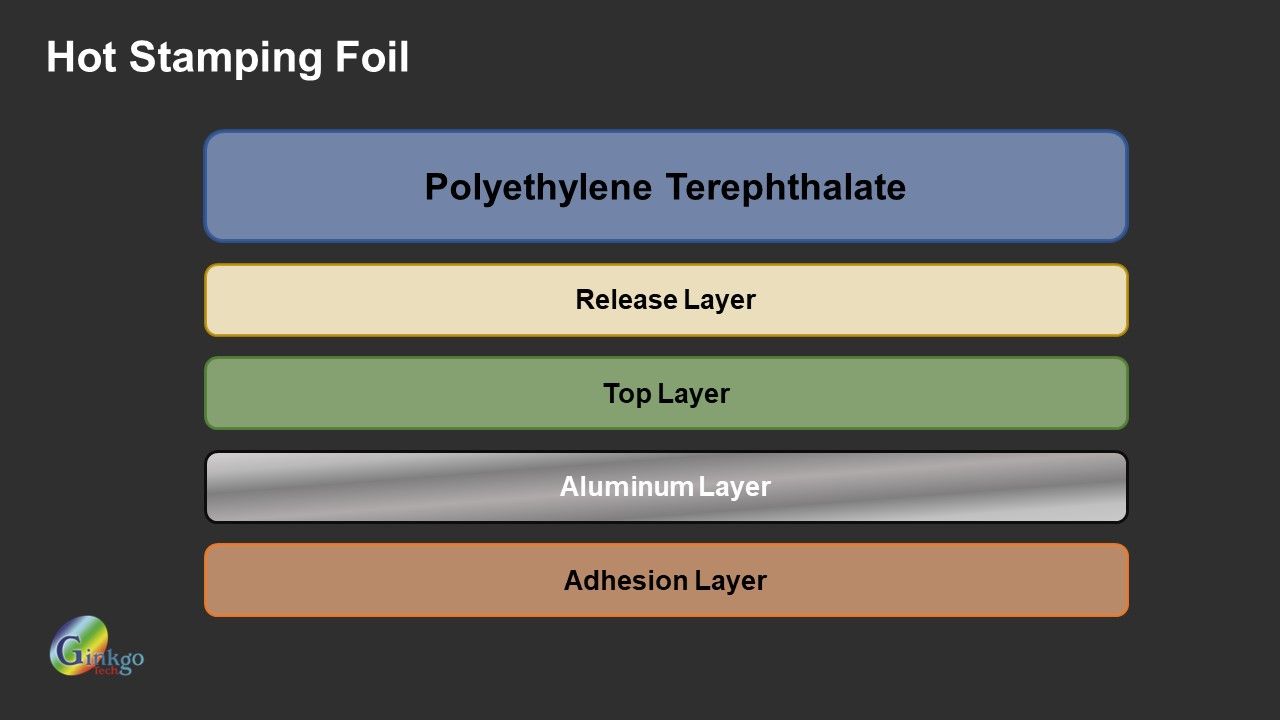

Hot stamping film for textile by partial transferring the metal on film onto the substrate, it gives the metallic texture and shine and adds values to the products. What's different to transfer film for textile is that the stamping process is easier and hence it is usually used in stamping patterns onto elastic bandages, textile, ribbons for gifts, T-shirt, fashion outfits, etc.

With different textile it needs distinct film to achieve the best quality, like ribbons and textile use different foils due to their different properties. Textile needs frequent cleaning and washing so fastness to these processes is important. On the other hand, ribbon doesn't need this property but needs good adhesion. We conduct all-round inspections to ensure safety of your products in the market.

Features

- Good resistant wash fastness.

- Excellent adhesion.

- Enables high gloss.

Specification

- Types of Suitable Material: Textile, Fabric

- Colors: Gloss / Matte metallic color and so forth.

- Hot Stamping Temperature: 100°C - 250°C

- Standard Size 1500mm x 1000M.

Ordering Information

- Minimum Order Quantity: Depending on required specifications. (Please contact our sales representatives for confirmation).

- Lead Time: Defined productions and inspections are based on your requirements. (Please contact our sales representatives for confirmation)

- Video