What Is Hot Stamping Foil?

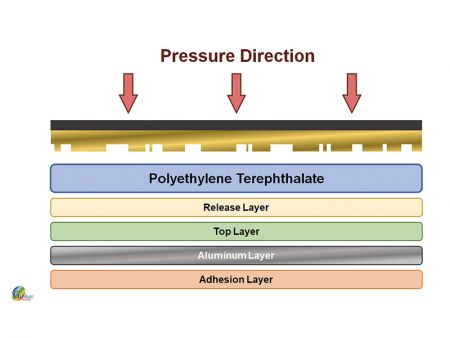

The three major elements of hot stamping are temperature, pressure, and time. Hot stamping foil is the foil with metallic luster. Using high pressure and temperature to stamp the pattern on silicone rubber die with metalized layer and color layer onto the printed matter. It is functional foil with multi-layer coatings. Each coating layer has an unique function and together they achieve hot transferring effect. The structure and preservation methods of hot stamping foil are as shown below.

The Structure of Hot Stamping Foil

PET Film: To support each layer, usually made of PET (polyester film).

Release Film: Also known as separation layer. To separate PET film from Top / aluminum / adhesive layers. It decides pattern transferring.

Top Layer: Protective layer that decides colors and patterns.

Metalized Layer: Metalized electroplating layer. As 90% of the metallic luster of foil come from aluminum, it is also called "aluminum layer".

Adhesion Layer: Thermoplastic resin that attaches to the substrate, could be adjusted per substrate's properties.

Summary:

Release layer allows PET film to be separated and left coating layer attached to stamped objects.

How to Properly Preserve Hot Stamping Foil?

As hot stamping foil is incredibly fragile and the coating layers could not stand downward placement, heavy weight, or dropping. Moreover, 90% of metalized layer is aluminum which has poor resistance to acids, bases and oxidation, the metallic luster will fade when not being preserved properly. Hot stamping foil could be preserved several years when handling with care. However, the shine faded with time and hence we suggest to use them as fast as possible.

Summary:

Methods of preservation

1. Keep them upright.

2. Do not stack on top.

3. Keep dry. Avoid placing on the ground as moisture may affect the quality.

4. After purchasing, use them all within 1 year.

5. Keep them at temperature of 25°C to 30°C and below humidity of 75%.

6. Avoid direct sunlight exposure.

7. Avoid acidic or basic environment.

Gallerys

- Structure of hot stamping foil.

- Please void hot stamping foil from directly exposing to the ground.

- Related products

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.

Hot Stamping Foil for Glass and Ceramics

Hot stamping foil for glass and ceramics is often applied to lotion, perfume, wine bottle, vase, and similar products. Spread ink or UV varnish on the substrate and proceed with thermal hardened system or UV hardened system, and transfer the metallic foil by hot stamping. It has better metallic luster and more outstanding colors than in general glitter printing process.

Holographic Foil

Holographic foil requires excellent hologram embossing technology to display a special appearance and catch customers' attention. The foil is often used in hot stamping on various papers and plastic materials and facilitate decorative functions. It could be applied to cosmetics, paper box, lure bait, credit card, passport, and anti-counterfeit label, it is flexible and available for satisfying different, customized layouts, colors, and patterns.

- Realated Applications

Plastic hot stamping foils for packaging design applications

Suitable for containers, packaging, labels, designs, cosmetics

Plastic hot stamping foils have been utilized widely in packaging materials such as cosmetics and skincare products. Because of its eye-catching metallic effect and diversity of colors, not only standard golden and sliver but also the popular rose gold and holographic colors. Furthermore, Ginkgo's plastic foils have strong alcohol resistance, scratch resistance, and abrasion resistance, preventing the foils from peeling off from the container because of the touch with cosmetic contents.Cosmetic like eyebrow pencils, eyeliners, lipsticks, creams, powder boxes, Etc., often uses plastic hot stamping foils for embellishment. Gingko's plastic hot stamping foils' perfect adhesion can offer the best solution to stamp on various plastic substrates like tubes, rigid plastics, PE, PP, PS, Etc.Thanks to Ginkgo's high-performance foils and comprehensive service, our hot stamping foils for plastic have been favored by famous brands, plastic injection factories, packaging material factories, hot stamping factories, design firms, and other industries.Ginkgo's plastic foils make your products stand out on the shelf and protect them with excellent resistance.

Plastic hot stamping foils for appliances and electronics

Suitable for white goods and black home appliances

Plastic hot stamping foils can decorate electronic appliances with a clean and modern appearance and stimulate consumers' desires. Ginkgo's plastic foils are commonly used in household appliances such as air conditioners, vacuum cleaners, televisions, refrigerators, etc. And mainly suitable for PP, ABS, PS, PVC, PE, and HIPS substrates.While offering a metallic look, the foils also have excellent resistance to prevent any damage or wear caused by using them. As a result, Ginkgo's plastic foils for house appliances must have outstanding scratch-resistant, abrasion-resistant, heat-resistant, and supreme durability.Because of validations and approvals by the highest standards, our plastic foils are always the priority choice for international brands, electronics factories, household appliance industry.