Types of Hot Stamping Machine

Hot stamping is a process to stamp the embossing patterns with metallic shines of the foil onto substrates by high heat and pressure. There are up and down stamping, vertical stamping, and digital stamping to choose from per products' needs. Detailed information of these three methods are shown as below.

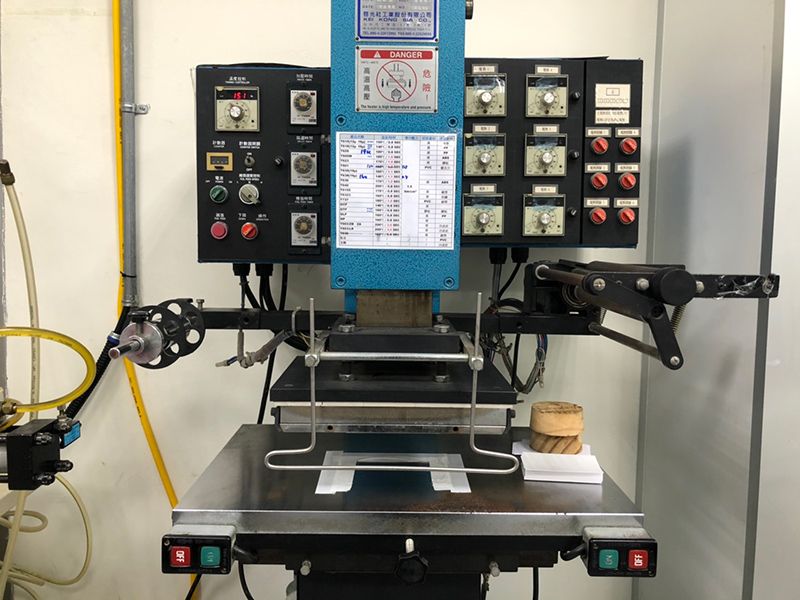

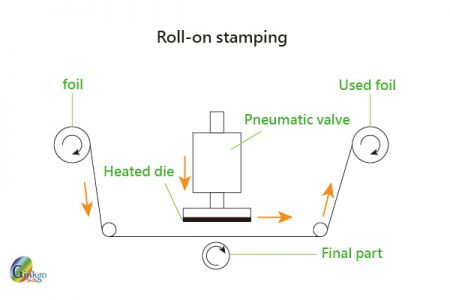

Roll-on Stamping

The roller is mostly made of silicone rubber. Stamping speed is 60mm per second. Suitable for cylindrical objects such as wine bottles, eyebrow pencils, and cream boxes. It is often used for packaging.

| Roll-on Stamping | |

|---|---|

| Production efficiency | Low |

| Adjustment and calibration | Hard |

| Cost of plate making | Low |

Summary:

It takes longer to adjust and calibrate the machine but the cost is relatively low.

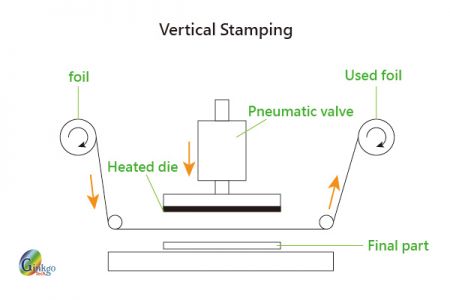

Vertical Stamping

It is a common approach. Stamping pressure is 50 kg/cm above. The benefits are simple structure, easy maintenance, and convenient for replacing parts. It is often used for objects with smooth or uneven surface such as magazine covers and uneven/curved surfaces. It is adopted for most of household appliances.

Summary:

It has wide applications, especially for household appliances.

Digital Stamping

Digital stamping is also known as plateless stamping . It is suitable for one off, customized needs. First, input the computer with the patterns to be stamped, perform hot stamping in ink-jet printing process. Only those part sprayed with varnish will have the color of the foil. It does not need plate making, has the benefits of low cost, quick proofing, and high flexibility. The technology is often applied to products like flyers and stickers.

| Hot Stamping Machine | Digital Stamping Machine | |

|---|---|---|

| Plate making | Yes | No |

| Sampling | Slow | Fast |

| Adjustability | Low | High |

| Paper adaptability | Good | Average |

Summary:

Plate making is not required in digital stamping . Often applied to small batch production of graphic products.

- Related products

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.

Hot Stamping Foil for Glass and Ceramics

Hot stamping foil for glass and ceramics is often applied to lotion, perfume, wine bottle, vase, and similar products. Spread ink or UV varnish on the substrate and proceed with thermal hardened system or UV hardened system, and transfer the metallic foil by hot stamping. It has better metallic luster and more outstanding colors than in general glitter printing process.

Holographic Foil

Holographic foil requires excellent hologram embossing technology to display a special appearance and catch customers' attention. The foil is often used in hot stamping on various papers and plastic materials and facilitate decorative functions. It could be applied to cosmetics, paper box, lure bait, credit card, passport, and anti-counterfeit label, it is flexible and available for satisfying different, customized layouts, colors, and patterns.

Exterior Foil

Exterior foil has strong environmental resistance and oxygen resistance and it is good for hot stamping on exterior and interior accessories of vehicles or outdoor objects, such as automobile interior decoration, automobile exterior garnish trim, chromium decoration, etc.