The Abnormal Situation During Foil Stamping

There are many types of defects. Below provide information regards two major defects that take place very often. One is "entrapped-air" which the voids are generated and trapped on the surface of the foil. Secondly, when perform hot stamping process on exquisite items, it tends to generate foil flake.

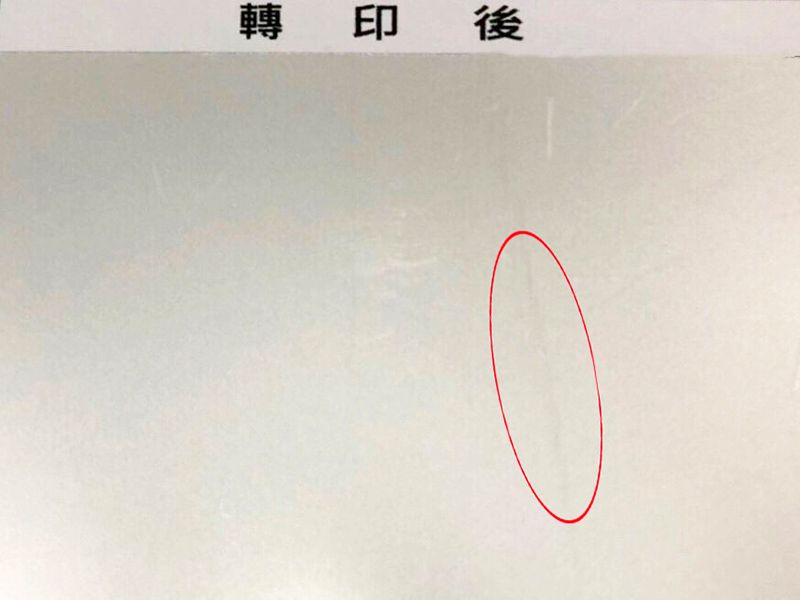

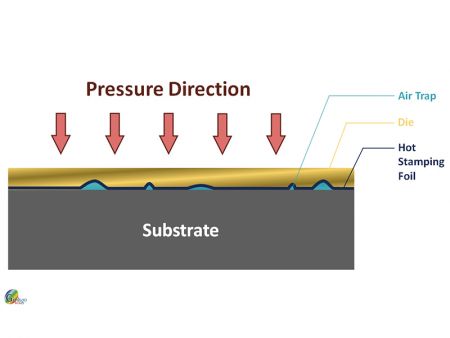

Entrapped-air Generated During Hot Stamping Process

The voids were stuck into the film during the process. The air couldn't go out and will break during hot stamping process.

Due to its vertical working moves, this defect is often found in up and down hot stamping process.

Summary:

To adopt model number - GV series to solve this issue.

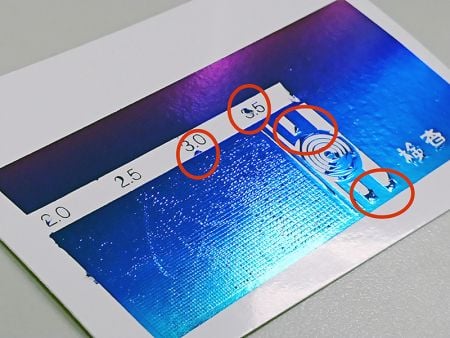

Foil Dust Generated During Hot Stamping Process

Foil dust is often found when performing hot stamping on exquisite fonts or patterns. Due to the easy release of the foil and the high working pressure / temperature, causing flake on the edge of the object which is known as foil dust.

Summary:

Choose foil with tighter velease, or adjust temperature and pressure when not changing the foil.

Gallerys

- Stamped surface breaks due to the entrapped-air.

- Entrapped-air.

- It cost more to clean the dust, it's also hard to fully remove it.

- Related products

Plastic Packaging Hot Stamping Foil

Hot stamping foil for plastic packaging has high chemical resistance and good adhesion to various plastic materials so the trademark or logo of the products won't come off. Suitable for industries such as cosmetics product packaging materials, household appliances and so forth.

Hot Stamping Foil for Glass and Ceramics

Hot stamping foil for glass and ceramics is often applied to lotion, perfume, wine bottle, vase, and similar products. Spread ink or UV varnish on the substrate and proceed with thermal hardened system or UV hardened system, and transfer the metallic foil by hot stamping. It has better metallic luster and more outstanding colors than in general glitter printing process.

Holographic Foil

Holographic foil requires excellent hologram embossing technology to display a special appearance and catch customers' attention. The foil is often used in hot stamping on various papers and plastic materials and facilitate decorative functions. It could be applied to cosmetics, paper box, lure bait, credit card, passport, and anti-counterfeit label, it is flexible and available for satisfying different, customized layouts, colors, and patterns.

Lamination Film

Lamination film could be fully attached to various substrates such as plastic and paper, allowing them to exhibit gloss. The difference between hot stamping foil and lamination film is the PET film layer is kept after the laminating process, leaving an extra protection to the surface of the products, keep moisture and oxygen away. It could work as a protective film. It also has better abrasion resistance and scratch resistance than general hot stamping foil, and have great adhesion to various substrates such as labels, greeting cards, wine bottles, packaging paper boxes, lampshades, etc.